Productive cycle

We follow the rhythm of purity

Lauretana water is bottled at more than 800 meters high, not far from the source. This is a conscious choice, aimed at preserving the original purity of this precious resource, thus maintaining intact its organoleptic qualities.

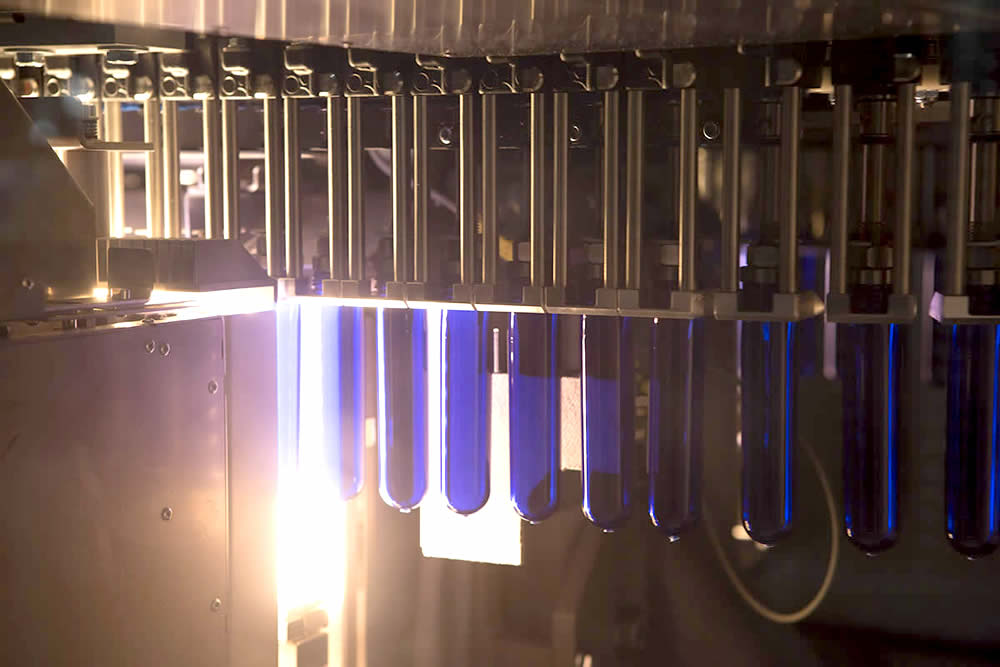

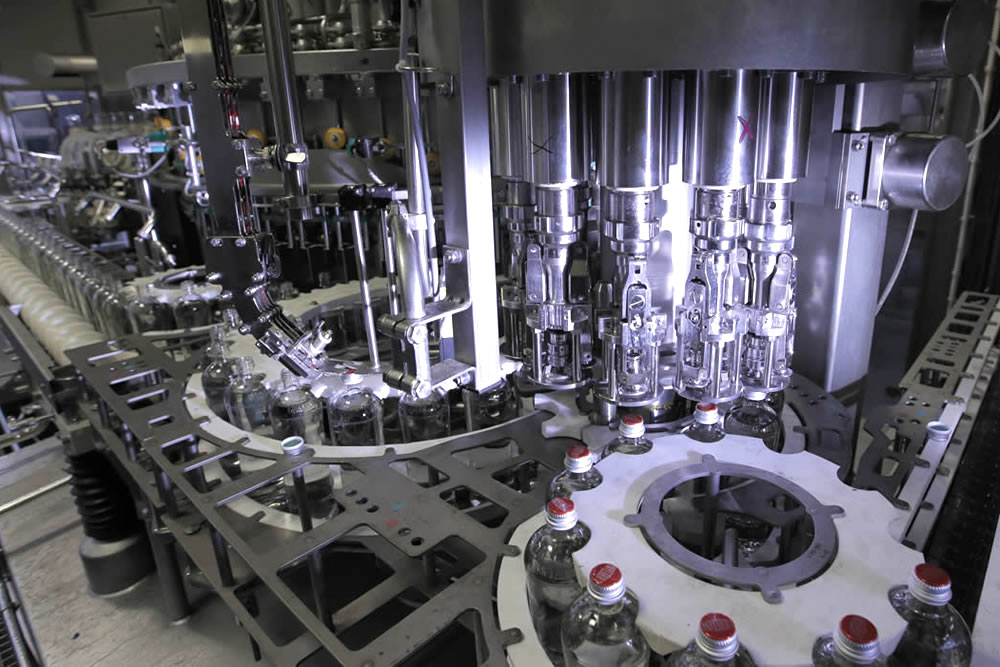

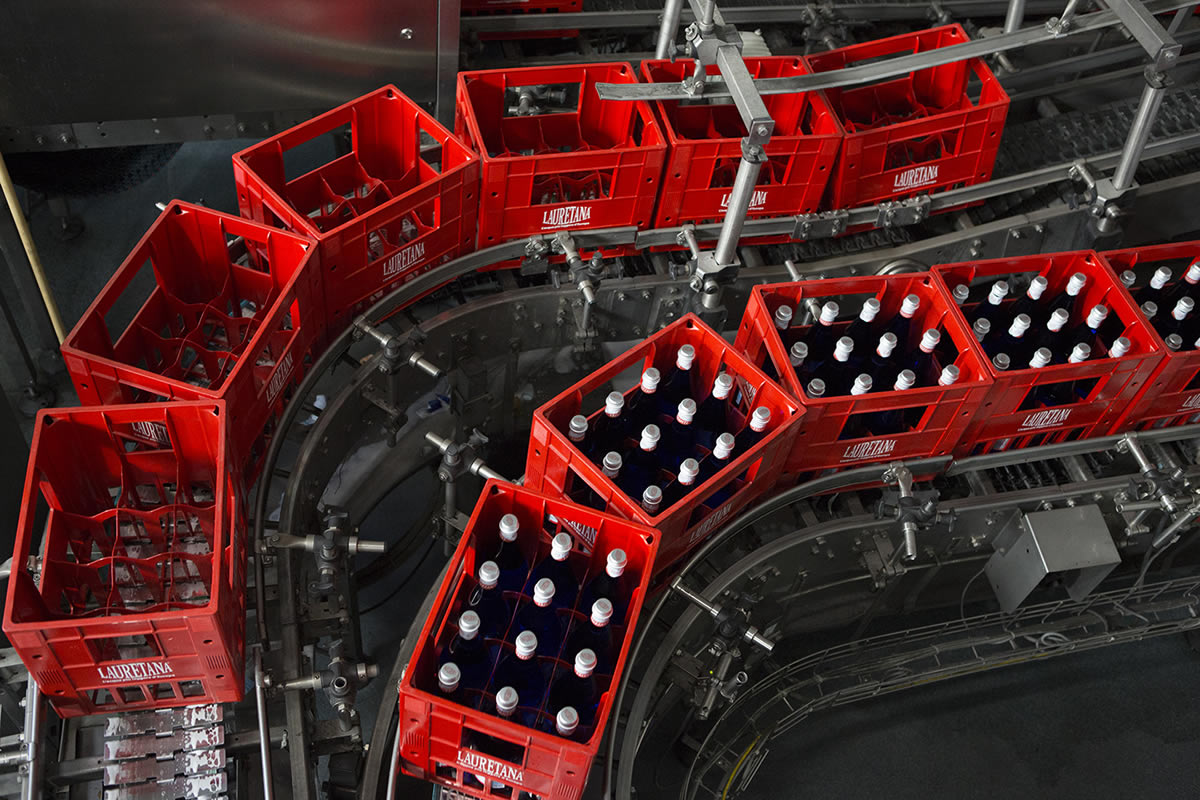

Completely renewed and high-tech lines of production, with systems of control of latest generation, grant the highest standards of quality, safety and respect for the environment. In the plant there are 2 lines intended for 100% recyclable PET packaging and 2 intended for glass packaging, both returnable and one-way (the last one addressed mainly to the international market).

The continuous technological investment is aimed at granting a more and more sustainable production, aspiring to the water and energy saving. Together with this virtuous entrepreneurial choice there is a careful and responsible management of each single waste material that is accurately separated and recycled, in order to be able to reintroduce it at the beginning of the production cycle. The respect for the alpine territory as well as for the sources, is also deduced by another aspect which is not irrelevant: Lauretana respects the seasonal flow of the waters from the sources strictly following the precious rhythm of Nature.

For research materials about sustainability, click here.